Turboden: Large Heat Pumps for the Industry

Decarbonizing heating processes is one key issue in achieving sustainability. The public discussion now mainly focuses on the heating of private households, as seen in the lively debate about Germany’s recently passed “heating law”, in which German lawmakers make it mandatory for new buildings to use sustainable heating sources such as heat pumps.

Industrial processes should be included in this discussion. However, they play a huge role in energy consumption, and additionally, traditional heat pumps fail to achieve the high enough temperatures needed in many industrial processes.

Here, the Italian firm Turboden comes into play. Turboden is an Italian firm and a global leader in the design, manufacture, and maintenance of Organic Rankine Cycle (ORC) systems, highly suitable for distributed generation, which produce electric and thermal power exploiting multiple sources. Thanks to its long experience in the energy efficiency sector Turboden expanded its solutions offering with gas expanders and large heat pumps. Since 2013, they have been part of Mitsubishi Heavy Industries, the company’s major shareholder. Today, we talk with Emanuele Mazzola, who is a Sales Engineer at the Heat Generation Business Unit of Turboden.

What is Your Product?

The heat pump extracts heat from a source, such as process streams, geothermal energy stored in the ground, nearby water sources, or waste heat from an industrial process. It then amplifies and transfers the heat to where it is needed. Because most heat is transferred rather than generated, heat pumps are far more efficient and thus cheaper to run than conventional heating technologies such as boilers or electric heaters.

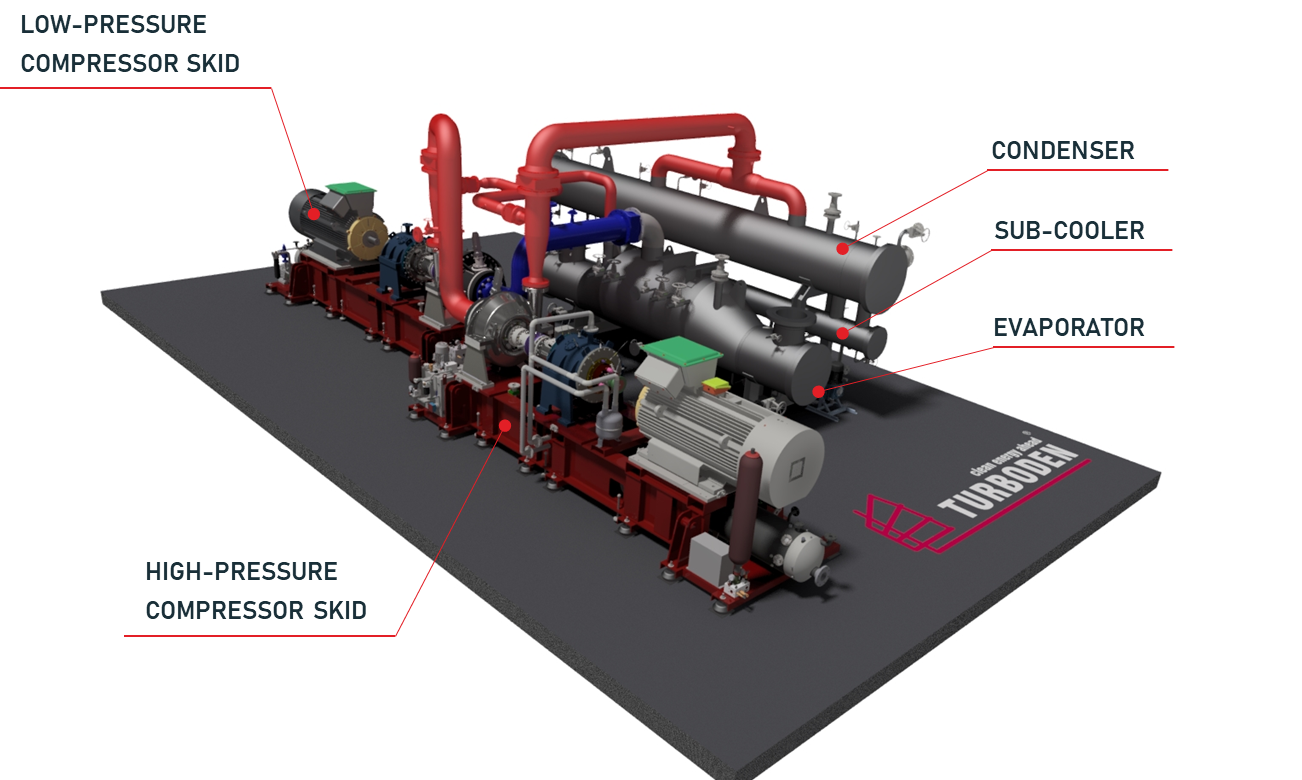

Our heat pumps target large capacity and high-temperature processes as our heat pumps can have a temperature lift higher than 100°C – this is a huge lift compared to standard air-to-water heat pumps used in residential buildings, raising the temperature by approximately 30°C. This is possible thanks to the implementation of different cycle configurations depending on the temperature lift to achieve. Higher is the temperature lift to achieve higher the complexity of the configuration.

Our compressor is an Integrally Geared Centrifugal Compressor (IGCC), part of the Turbo compressor family. It provides the highest isentropic efficiency out of all compressors in the heat pump industry and it is the only suitable for Large Thermal capacities. This leads to large thermal capacities of up to 40 MW thermal power (MWth) per single unit with the possibility to generate steam.

What are the Applications of Your Heat Pumps?

Our application area is primarily industrial processes and heat district networks, as we provide heat pumps for large-capacity and high-temperature processes. In the industrial scale products, we are mainly involved in the food industry, the paper industry, and various branches of the chemical industry, such as petrochemistry.

Our reference for district heating applications is located in the Italian town of Brescia. The 6 MWth unit is in a steel mill plant, where we use the cooling water from the electric arc furnace as the heat source. The water is cooled in an evaporator from 75°C to 70°C, and the amount of heat released is used to produce pressurized hot water at 120°C, used in the city’s district heating network.

We have also a reference in the steam generation application. It is a heat pump in a paper mill in northern Europe which produces superheated steam for the drying process of the paper. We utilize an intermediate water loop (17°C-8°C temperature profile) which takes the heat of wastewater and Exhaust air from the paper mill process as heat source. The heat pump produces steam at 1,6 bar from a condensate stream and the residual temperature lift is achieved through a mechanical vapor recompressor, which brings the pressure up to 3,5 bar (170°C). The plant is under construction and the start-up is expected in Q4 2024.

This sector and other big players across various sectors are increasingly committing to decarbonizing their processes in the coming years, and we are sustaining them during this transition to electrification.

What are the Biggest Challenges Your Company is Facing?

One of the main challenges today is the electricity/gas price ratio. In countries where this ratio is high, we experience a low interest in heat pumps. Nonetheless, the removal of subsidies to fossil fuel energy generation and the detachment of electricity generation from them will contribute in the following years to the decrease of this ratio. We expect the carbon tax on fossil fuel use to increase over the next few years steadily.

Which Future Plans Do You Have?

We want to make our large heat pump a standard solution for industrial processes that need process heating below 250 °C, as well as decarbonize district heating of the major cities in the world. We think the electrification of heating generation is the future of low-temperature heating processes.

Whom to contact?

Are you feeling inspired by this exciting idea and eager to explore more? Reach out to Emanuele or visit Turboden to learn more about their work.