Framatome: One Day at the Nuclear Reactor

In the search for ecologically friendly solutions, nuclear energy is the arguably most disputed solution: A French initiative led the EU to declare nuclear energy to be green, Poland just gets started with nuclear power, and many other countries, as the Czech Republic ramped up their repertoire. In stark contrast, Germany, the biggest economy in the EU, just closed its last nuclear power plants. The German government tried to veto France’s initiative to make nuclear power a green energy source.

Fear, Hope, Sustainability, Geostrategy, Engineering, and Physics – all these and more play a crucial role in this passionately discussed topic; any of these aspects literally book volumes.

In today’s interview, we want to explore a different aspect of the field: What does one day of work in a nuclear power plant look like? We are speaking with Adrian Rönsch, working at Framatome, about his experience in one of the most regulated workplaces.

How did you end up working in a nuclear reactor?

I was passionate about energy technology from a relatively early age and became increasingly interested in nuclear technology. Through a conversation with an acquaintance who works in procurement at Framatome, I came across the working student position. I got a contract in the 4th semester and have worked in the I&C, the Instrumentation and Control Department, ever since.

Where does the fascination with nuclear power come from?

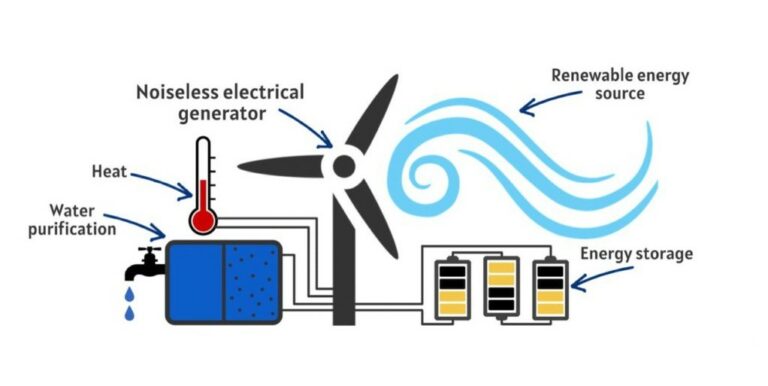

I find renewable energies exciting, but the biggest problem is cushioning peak performance. In general, many things having a low efficiency and need to be improved. Please do not get me wrong. There are a lot of interesting and high potential technologies out there but in my eyes non is that far that is will resolve all of our energy problems but just scaling it up. On the other hand, fusion energy is an exciting field, but it is a research field far removed from industrial production.

Nuclear power brings together a whole range of fascinating things: A massive amount of energy is bundled into tiny amounts of material – 1kg of Uranium 235 holds the energy of 2.700.000 kg of coal ; the complexity of the control and the fact that the technology is already ready for use today. In the development area, many different variants of reactor types have been tested on a small scale, leaving the main focus on scaling them up for mass usage.

Purely in character, I’m not someone who would devote myself to basic research; I’m interested in what can be implemented: scaling, making things big, and seeing that it works. On the one hand, there is a great need in the context of climate change; on the other hand, the basic possibilities already exist.

What do you want to contribute to nuclear power in terms of development?

My big vision, where one can argue about its realism, is to use nuclear power to cover most of the world’s energy needs. Different types of reactors are to be included, including current power plants. Primary reactors are supposed to recycle the spent fuel rods and thus also process the long-radiating fission elements in the reactor. Through a largely energy-positive chain of reactor types, we would end up with minimal nuclear waste that would last less than 300 years. The current repository buildings are currently certified to last 100 years. You would then have to go through only 3 cycles to store it for good.

In this direction, I see myself in developing new types of reactors, i.e., molten salt and breeder reactors.

What are you currently doing at Framatom?

I work in the I&C (Instrumentation and Control) department. My daily business consists of completing design tasks for control technology. This ranges from working on earthquake calculations for control cabinets to designing packaging and gripper arm systems for a robot that walks through contaminated buildings or designing switches and cable glands for areas with extremely high levels of radioactivity. These parts are not simply purchasable.

I have contact with the reactor plants during assembly trips for maintenance or modernization, where I am there to help. My last assignment took place at the Borsele nuclear power plant in Holland, where I carried out leak tests on the control element drives on the reactor lid, as well as maintenance and inspection work on the coils that raise and lower the control elements.

How much power do your reactors have?

The most recent EPR-3 developed by Framatom has an (electrical) output power of 1600 MW. The reactor in Borsele where I worked is a reactor from KWU Siemens, a predecessor company of Framatom, which has an electrical output of 512 MW. It is a Pressurized water Reactor with the technology of a steam circuit power plant, which is generally quieted slow to regulate in terms of Power. The power plants do not always run at rated output – for example, during the coronavirus pandemic, the regulation was lowered somewhat due to the reduced energy demand – but for the most part, the power plants are running at almost full load. However, there is a certain degree of leeway. Nuclear power plants tend to run more stably than gas power plants, which are used flexibly to cushion peak performance. This means that our power plant produces energy over a day of more than 10 GWh.

Starting up the power plants takes around five days, and shutting them down is relatively quick – the thermal output of the reactor can be reduced to 0 within a few minutes. The standard temperature in a pressurized water reactor is 320°C at 160 bar. This temperature is initially not reached by the fuel rods temperature but by the coolant pumps pumping the water, and the friction of the water causes this temperature to be reached, and only then does the nuclear chain reaction begin.

What does a day at the power plant look like?

We are talking about the working day of an engineer who enters the power plant during an outage, not that of a typical operator. The work begins when you enter the area: verify yourself with your ID card at the barrier. The steps leading up to the ID card are a very bureaucratic process that involves a lot of training and approvals: you need a demarcation agreement, radiation protection instruction, an examination, and various training courses that cover wearing breathing apparatus and working in conditions where there is a risk of falling.

For us, a container castle is usually set up on the power plant site as a mobile office, where we put our stuff and hold meetings – we discuss the current status at the place of work, what we want to do, and what the goal is and what the possible dangers of the task are.

Then you pick up your work permit in the office – nothing works in the power plant without a work permit. The whole thing makes much sense, for example, to prevent someone from working on one pipe and someone from starting up a pump at the other end.

You then enter the power plant building. A day at the nuclear power plant differs from most other working days in that you first change entirely in a changing room, including your underwear. Control room underwear is provided so that no contamination is carried outside. The used laundry is thrown into a bucket and then washed. The control room underwear is orange and extremely ugly to deter theft. In your underwear, you go into a second changing room and get your overalls, which look like they do in the movies. The coveralls are color-coded to indicate levels of experience and radiation protection.

The actual check-in procedure begins: You receive digital and analog dosimeters to measure your radiation dose. You then get an initial measurement, which you can imagine, like a body scan at the airport, where it is measured whether there is radioactive radiation. Interestingly, this is also how the disaster in Chornobyl was discovered because the entrance scanners at a Swedish nuclear power plant were activated, and it was found that people entering were carrying radioactive isotopes on them.

Check-in takes at least 20 minutes, and check-out takes the same time. You have to keep this in mind because, in the control area, there are neither toilets nor food or drink to prevent incorporation, i.e., the absorption of radioactive substances.

Then, it goes into the “big ball,” i.e., the containment. The entrance is through a lock, the doors of which are opened hydraulically because everything is exceptionally thick to ensure that everything remains contained in the event of a core meltdown.

The containment contains:

- The reactor pressure vessel.

- The storage pool.

- The steam generators.

- The primary coolant pumps.

From then on, there is no stress, time pressure, or “this has to be done” – there is just highly calm, conscientious work, doing exactly what you agreed to beforehand. In any case, this is an exceptional feeling.

I found my job at the Borsele nuclear power plant on the top floor of the Containment. There are still specific barriers between work areas where you can change shoes so that it does not leave the corresponding area in the event of minimal contamination.

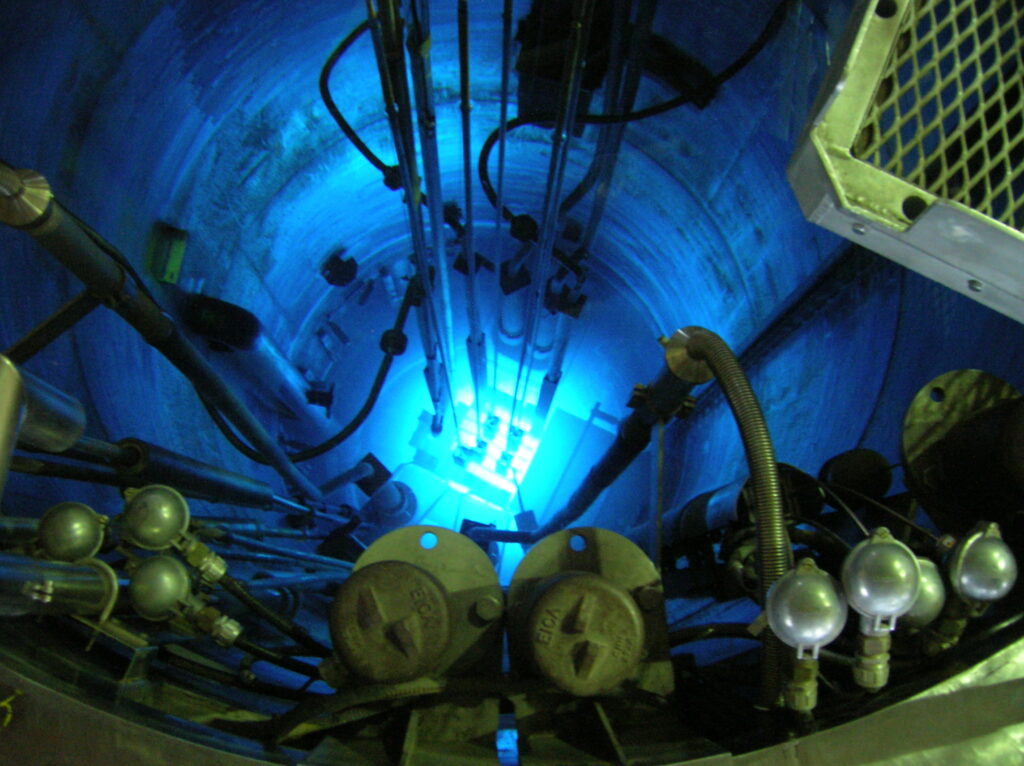

My workplace was at the edge of the reactor pool. The opened reactor is flooded with water, so the radiation does not come out. So you can look inside the entire reactor. It’s a magical workplace: you have the blue light of Chernenkov radiation, like a flash bang in the water. When you work on the pool’s edge, you become aware of the whole thing again: only about 5 meters of water between you and several tons of uranium rods, which are incredibly blue. The water is extremely clear, and you can see everything.

Then, the work begins: every step is discussed and planned.

In the normal control area, even at the edge of the reactor, there is an extremely low level of contamination. On a typical working day, you get less contamination than from cosmic radiation on a short-haul flight. In Borsele, however, we still had the problem that the reactor cover radiated relatively strongly on its own: the steels from earlier contained cobalt, and the cobalt was activated from Co59 to Co60 by neutron irradiation. As a result, the power plant started its components over time, which made my workplace a high-dose place for once. I could only work there between 30 and 60 minutes a day at most. I wore full body armor with fall protection and every breathing apparatus you can imagine. I plugged test plugs into coils so that voltage and current measurements could be taken and connected a vacuum test line to the bottom of the reactor lid. After the devices were installed, I waited until my colleague took measurements. Then we swapped: my colleague installed the devices, and I measured.

The work should be done as quickly as possible to avoid unnecessary contamination. It should be carried out without hesitation so that you don’t get injured and no mistakes happen: a dropped wrench would be quite a catastrophe, as every day that the power plant is not running, approx 1 million losses are caused. In the event of a dropped wrench, a submarine will be in the reactor during the outage – depending on where it falls, this can be a half-hour mission or a two-day recovery operation.

When you check out, remove your protective clothing and deactivate your work permit: you report what you have achieved. The various security gates then start backward. Ultimately, it is measured whether you have residual contamination on you. This is extremely unlikely and has never happened to me, but it would also be highly unpleasant. For example, people don’t shy away from cleaning their eyebrows with isopropanol for half an hour so that the contamination goes away – As long as you are above the limit, you can’t get out.

The same applies to measuring devices – if they cannot be cleaned, they remain in the control area, no matter how expensive.

By the way, the well-known yellow barrels of radioactive waste are mostly lightly contaminated: underpants, clothing, and towels. They are not barrels full of old fuel rods.

Whom to contact?

Are you feeling inspired by this exciting idea and eager to explore more? Reach out to Adrian for a delightful discussion.