Compular – Digitalizing Materials Development

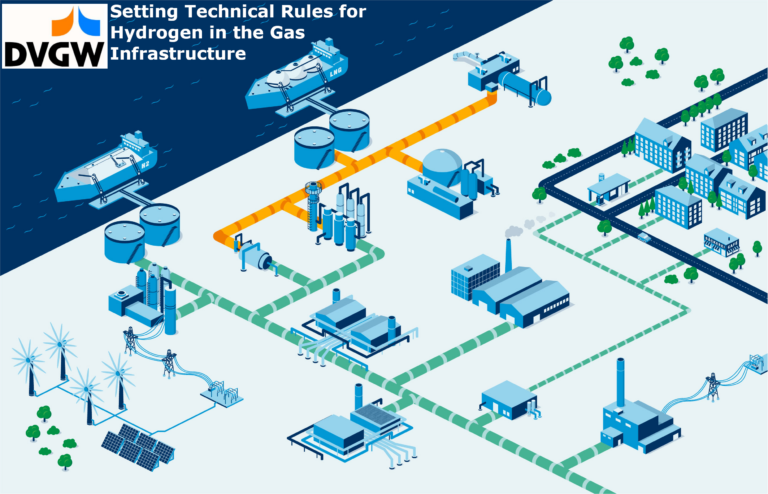

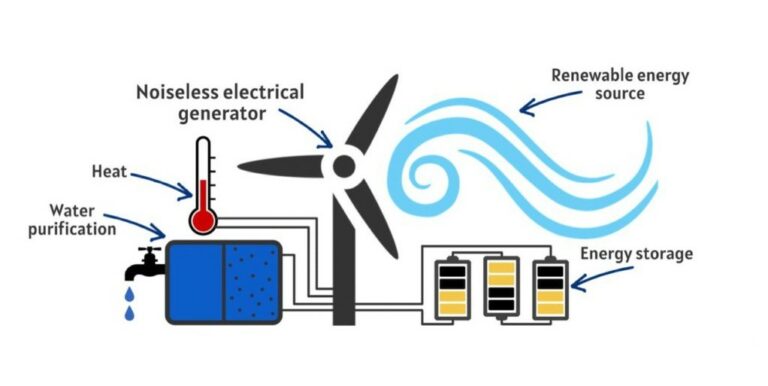

The main challenge of the energy transition is to decarbonize energy production and consumption in an economically feasible fashion. In production, the impact of renewable energies such as wind and solar becomes crucial—both of which are intermittent in nature, so the question of how to store the energy becomes prominent. On the consumption side, battery-powered electric vehicles are on the rise; requiring always better, cheaper, and more environmentally friendly batteries.

The Swedish startup Compular is set to improve battery development using their years of experience in research and business. In today’s interview with Compular’s CEO Rasmus Andersson we learn about their work.

Why Did You Start Compular?

Compular came about as a result of the research that I was doing at Chalmers University of Technology. Relatively late in my PhD, I made some big breakthroughs in analyzing simulations that seemed very useful both for academic and industrial purposes, and felt I had a lot of momentum to continue building on that. I really wanted to keep working on those developments, whether in academia or industry. Unfortunately, there is a very well-defined path you are supposed to take for an academic career: You’re supposed to go to a different country to work for someone else on a preferably completely different topic and drop everything you did in order to develop some kind of independence, which I felt that I already had from my PhD work. Also, with wife and kids, it wasn’t so easy to leave everything behind and go to a new country. So, my goals did not align with continuing in academia – and the only other route I saw to continue my work was to start a company. I thought: “Let’s see if it works. It might be nothing, but then, at least, I tried.” So far, it’s been going a lot better than I expected.

However, we quickly had to change our initial idea. When you meet customers, you realize that what they need is probably not quite what you thought. But we managed to find something quite interesting to the industry, and that’s very exciting.

What Was the First Idea You Had in Mind?

In my PhD, I developed a way to get much more value out of molecular dynamics simulations. These simulation methods were already well established, and they output gigabytes of hard-to-interpret data. There were standard ways of translating how atoms move into material properties, but there was so much they could not do which they should be able to. I extended these approaches by finding what moves together and analyzing that. This allowed us to predict material properties accurately with much less data, while at the same time bringing much more mechanistic insight. This felt quite valuable to me, and the original idea was that we would sell analytics software to companies who were already using this kind of simulation. But when we spoke to the battery industry — as opposed to battery academia—we quickly discovered that virtually no one did these simulations. This led to our first pivot.

What is Your Product?

Our main product today is a web app. We are running all the heavy compute in the cloud, which means that as a user you only need your laptop with a browser, and because all the tricky parts are automated and heavily optimized for accuracy and efficiency, this brings down the barriers to entry for companies that don’t already use such tools. The only things the user is required to specify is the kind of things that they would anyway need to know in order to do the corresponding trials in the lab. This means any R&D scientist can use our software, even if they don’t know the first thing about computational physics or chemistry. The idea is to eliminate 95% of your candidate formulations, materials or molecules using our software and then only bring the most promising 5% into the lab for validation. Thus, companies can get 20 times as much done by using our software. That is our first use case.

Another use case is to provide high-quality material parameters for cell simulations: Many companies run their simulations not on the material level but one level up, on the cell level in the context of batteries, and for this, they need material parameters. Some of those are very hard and expensive to measure, especially when it comes to the electrolytes, where our capabilities are the strongest and best validated today. This allows our customers to use cell models not just for mass produced cells, but also as a central part of their R&D work while developing new cells in a much more practical way than was possible before.

What is the Toughest Challenge You Face?

Timing is a big challenge: The basic types of simulations we rely on have been practically in use in research for 30-40 years, and have resulted in Nobel prices since the ‘90s. However, they are still by and large not good enough to make sense for industrial players in the way they are usually applied. They also require very extensive manual work from highly specialized experts in order to reach that bar. We have been told by multiple companies that even when they have hired whole departments of computational chemists, in the end they haven’t been able to contribute tangibly to the main R&D process. It is still very challenging to provide high-enough quality simulations, for them to be reliable and actionable enough for industrial companies to really push the pace of R&D progress. Based on our experience of speaking to potential customers, our perception is that our competitors largely miss that bar today, especially in fields where these computational tools are not yet well established. They have had more success in a few fields, e.g. pharmaceuticals, but only because enterprise pharma have already hired big teams of experts and got used to this level of cost. We have over time been able to consistently reach the required quality level in our targeted application areas only by working very closely with our early customers, and have built the tooling to enable us to generalize to more application areas over time with the same high quality and automation. Eventually, this will enable us to help also pharma companies become much more productive in their work.

Another challenge is to prioritize between all the further functionality that our customers request. There are so many ways in which we could help them eventually, but they all require further development work. Our approach is to prioritize based on how many companies want the same thing and on how fast we can build something that is good enough to serve their needs. This means that our scale-up process as a company has to be a dance between tech and sales work where we cannot simply sell first and build later, but need to be mindful of what factor is the bottleneck in each case.

Which Future Plans Do You Have?

We just recently launched our software, and we want to bring that to more customers. That’s one of our priorities right now. In addition, there are still a lot of things it doesn’t do that we know that our customers want. So we want to expand our capabilities. For example, there are the concepts of SEI (Solid-electrolyte interphase) and CEI (cathode-electrolyte interphase), which are thin films that form on the electrode surfaces, and are critical for the longevity of the batteries but are beyond the current state of what simulations can handle. It would be really, really useful for them to do so, as they are also very hard to study experimentally. You can determine the longevity experimentally, but you do this by running lots of cycles and seeing if it lasts or breaks, and when it does you don’t know why. It takes months and is very expensive because you have to let it age. Here, our simulations will bring understanding and predictive capability to the table in a much shorter time. That’s one of the development tracks we are on now, and we do this by predicting the chains of chemical and electrochemical reactions that occur in the cell. Our long-term goal is a fully dynamic model for SEI and CEI formation. In the short-term, we want to gain insights into what kinds of reactions happen and find correlates of good and bad SEI and CEI as a function of the combination of species you put into your cell.

We also recently strengthened our team in the areas of solids and polymers which will enable us to handle more components of a cell, and also facilitate expansion beyond the battery industry. Overall, there is a lot of focus on technical development, which has been greatly facilitated by recently being accepted into the European Investment Council (EIC) accelerator program, which combines a big grant with the later opportunity for an investment from the EU. As this program focuses on bringing up the technological readiness level (TRL) of deep tech products, it is a very good match for us.

Also, we are exploring in the early stages whether it is a good go-to-market strategy to partner with companies that do continuum-scale modeling on the cell level and combine our product with theirs. The idea is that our software predicts parameters that can then be put into these other companies’ models. That way, our customers can get better help by adding the next layer on top of ours, and the partners’ customers can get better help from adding the bottom layer that they often lack today so that the output of their models are closer to reality. In addition, this might be a good way to start to get some exposure outside of the battery field, since many of these companies have a broader customer base. It will be interesting to see where else there is interest in our solutions.

Whom to Contact?

Are you feeling inspired by this exciting idea and eager to explore more? Reach out to Rasmus for a delightful discussion, or simply visit their website to learn more.